I am from Uk! This is my first trade in China. I choose Haomei as the manufacture, at first I just hope I would not disappointed, however Haomei gives me a big surprise, the goods, the packing, the payment, the delivery and so on, all what I want to say is" Thank you very much"!

About Product

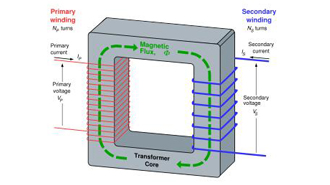

1.Aluminum and copper are the two conductors most commonly used in transformer windings. it is more economical to build the transformer windings with copper or with aluminum. In distribution transformers, aluminum foil windings have been successful. To select the right material, the designer has to take into consideration several factors such as weight, maximum size, transformer total cost, availability and cost of the material.

2.In a transformer that uses LV and HV aluminum windings, aluminum foil is a common component. HV windings are wound from aluminum foil that is combined with an insulation foil. LV windings are wound from single-aluminum sheets and combined with a cast-resin fiberglass fabric. Windings that use foil are exposed to less electrical stress than other windings that result in higher AC and impulse voltages.

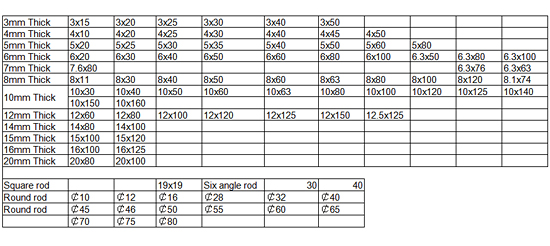

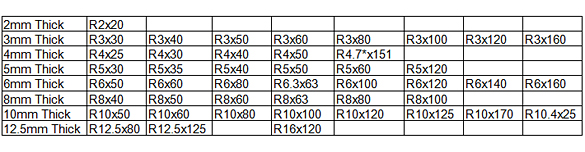

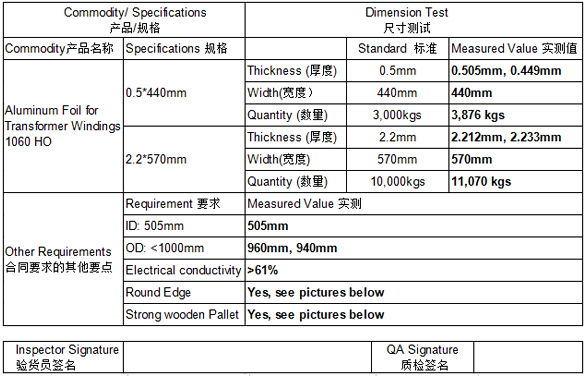

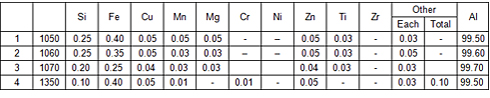

3.Using our advanced equipment, we provide clients with premium aluminum foil for transformer windings. We supply in different series, including 1050, 1060, 1070, and 1350. Each of these are made with tempers HO (soft) and both side edges of the aluminum foil are round without burr, as well as manufactured and certified to ISO9001:2004 Quality Management Standards. With a monthly output of 800 tons, we can easily meet clients' needs. We also supply aluminum foil strips, aluminum bus bars, etc.

-

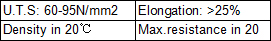

Mechanical Property

-

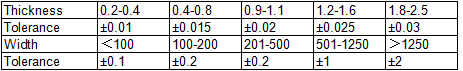

Tolerance for Thickness and Width

-

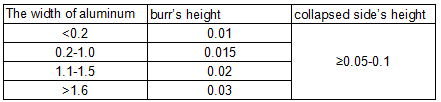

Burr and Collapse

-

Aluminum Foil

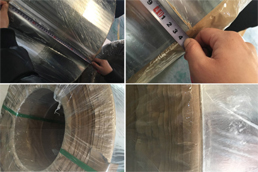

Our aluminum foil meets the strictest requirements featuring smooth edges, careful packaging and guaranteeing aluminum composition and temple designed for transformer applications.

Our most commonly used product is 99.5% aluminum composition but we can offer up to 99.7% aluminum. -

Chemical Composition (Standard: GB/T 3190-2006)

-

Finish

The material shall be clean, bright, smooth and free from joints and harmful defects. Edges shall be free from burr and shall be rounded.